J-WAFS in action – combating food contamination

Tim Swager, the John D. MacArthur Professor of Chemistry at MIT, and coworkers, have developed a new way to bring a fast, easy, and affordable food safety sensing technology to industry and consumers.

Funded by the Abdul Latif Jameel Water and Food Systems Lab (J-WAFS), their research is based on specialized droplets — called Janus emulsions — that can detect bacterial contamination in food.

Abdul Latif Jameel Perspectives talked to Prof. Swager to learn about the project and its potential impact on global food safety.

Q: What is the main issue you are seeking to address with this research?

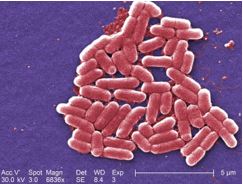

TS: The reason we get so many product recalls, particularly in the U.S., is that we don’t have the ability to test for pathogenic organisms like listeria, campylobacter or E. coli with sufficient sensitivity and speed before products have to be distributed to grocery stores.

(© Janice Harvey Carr, Center for Disease Control)

They have a limited shelf-life, and often must be stored at a reduced temperature – and it’s costly to interrupt that process.

There are numerous different food safety sensing technologies that are already on the market but considering the frequency of pathogen-based food recalls, it is clear that this problem has not yet been solved.

My idea was always that, if you’re trying to detect organisms or biological processes, it would be best if you could do it in a way that closely mimics their native environment. So that’s what we set out to do.

Q: Can you explain how your technology works?

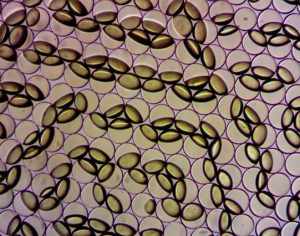

We work with complex liquid colloids. They are produced by dispersing tiny droplets containing two different oils in water, and then we assemble biomolecular recognition elements at the surface that act like ‘bait’ for pathogens or other organisms. We use these complex liquid colloids, which we also simply refer to as ‘droplets’, to bind to pathogens and use their relative organizations for detection.

We have made use of liquid droplets having equal amounts of the two immiscible oils in a structure we call the Perfect Janus Emulsion, wherein in there are two hemispheres of equal size. The oils that constitute hemispheres have different densities, which affects how they align, with the heavier oil being on the bottom. However, just like a privacy screen that you can put on your laptop screen these droplets only transmit images when viewed straight on with respect to their alignment. This is because they are, after all, liquid lenses.

What makes these liquid micro-lenses particularly unique is their ability to bind to specific bacteria proteins. Their binding properties enable them to adopt different orientations when bound to particular bacteria or proteins. These binding processes cause them to tilt and disrupt the “privacy screen like” orientation.

The result is that rather than transmitting an image they become opaque.

This macroscopic effect can be used with a smart phone and cause an image viewed through a layer of the droplets to become unrecognizable.

Alternatively, these tilted Perfect Janus droplets can be counted using image analysis and this method can give accurate measurements of the number of bacterial or concentration of the protein present.

Q: Why is this technology so disruptive to the food safety testing industry?

TS: To test effectively for pathogen-based food contamination, you need to test as frequently as possible.

If you’re testing one in every 50,000 units, you’re going to miss many cases of contamination. To test more often, you need a test that is fast, ideally in one or two hours – and that’s what we have produced.

There’s a big established market, and the current technology is inadequate in terms of speed, sensitivity, and cost. Our method represents a significant improvement on the existing technology, and it will potentially allow us to capture a large section of that market in the coming years.

Currently, our startup company Xibus Systems is developing protocols for field tests. Our goal is to provide a system that allows end users to operate in their typical fashion. We are striving to make it simple, fast, robust, require minimum training and not disrupt current operational structures and processes.

Q: Is the industry proving to be receptive to your ideas?

TS: Food producers are very open to new technologies. But this comes with the feature that it will very competitive to keep customers who are open to the next, latest, greatest, technology. You need to continually develop and innovate otherwise you will get left behind. So, a very dynamic market, but it’s an area where we think we can compete and potentially dominate. We have to create a superior product and, once we’re in the market, our job is to continue to innovate to stay ahead of the competition.

Q: Where else could your technology be applied?

TS: One of the most obvious areas is testing for ‘spoilage organisms. Spoilage leads to big losses for food producers, so a fast, effective way to detect spoilage organisms in a product will deliver considerable benefits.

It could also be used to check for contamination of food processing equipment. Our technology allows producers to swab pieces of equipment to ensure it’s been cleaned properly. So, if you’re making sausages in a large facility, for example, you clean your equipment and you want to make sure it’s all clean and back online as soon as possible. We can help keep the equipment operating and ensure the safety of the food being processed.

Q: Where do you see this technology going in terms of future development?

TS: The equipment we’re currently using, the first generation, is the size of a shoebox. Eventually, we expect it to be as small as a smartphone and for some of our applications the reader could actually be a commercial smartphone. For example, with higher concentrations of pathogenic organisms, you’d be able to quantify them through a photograph taken on a smartphone using a standard magnifying lens. You could check the bacterial count in a stream, for example, and immediately know if it’s okay to be given to livestock.

This technology is also applicable to healthcare. It could tell you if you have influenza or AIDS. We’ve already created a Zika virus test by recognizing a protein biomarker. It can detect other viruses, or proteins associated with different diseases such as gut-related illnesses in your digestive system. We envision producing do it yourself home tests using a smartphone and application software.

For commercial users, we’ll also produce an affordable platform that’s designed to sit on a benchtop and can allow you to analyze 100’s of samples simultaneously. Such a capability will be important if you’re operating a large-scale production facility and need high efficiency.

Q: What are its potential applications in less developed countries?

TS: Our methods are simple enough that they could have huge benefits in less developed countries. It can be applied to drinking water and all sorts of foods. For example, metastasis in cows is a big problem for milk producers all over the world. It can spread quickly through entire herds.

In India, for example, milk from a number of different herds in a region will often be combined at a central collection point. If one herd has metastasis, the entire batch is spoiled. Our technology would be able to identify metastasis in an affected herd before it contaminates unaffected milk.

The key thing is, it has to be really simple as farmers themselves will be doing this test. It also has to be reproducible even when conducted by people who may not pay attention to the details in the way that a trained scientist would.

Q: How important has the J-WAFS program been to the successful development of this technology?

TS: Our involvement with the J-WAFS Solutions Program has been vital. It has provided us with a bridge between the academic world and the business world and allowed us to perform more detailed work to create a useable application.

TS: Our involvement with the J-WAFS Solutions Program has been vital. It has provided us with a bridge between the academic world and the business world and allowed us to perform more detailed work to create a useable application.

J-WAFS Solutions’ funding specifically allowed us to undertake a field test on live Salmonella bacteria under real conditions with the US Department of Agriculture.

We took our portable spectrometer and droplets to their facility in Pennsylvania, and it worked first time. This demonstration proved to us that the assays work in the real world. These are not the kind of studies you will do under a typical government research grant. So, these J-WAFS sponsored studies gave me and my team the confidence to seek commercialization and the company Xibus Systems was born.

Q: What comes next?

TS: There’s a good chance that we’ll have at least one customer field test completed by the end of this calendar year. We will be conducting demos with prospective customers on an ongoing basis and seek to add additional customers in different sub-spaces by the beginning of next year.

Once we get significant customer buy-in, we should be able to start scaling up for larger-scale droplet production. However, the fact that we use such small amounts for each test, these scale-up processes will be conducted in a standard laboratory and will not require major capital.

We have some very good seed investors, and our funding will run out in late spring. So, we need to establish that we have customers in hand to optimally raise the next round of financing. This is the reality of the start-up! You have inflection points where you have to demonstrate capability and thereby create value in order to attract additional funding.

I think we’re on track.

1x

1x

Added to press kit

Added to press kit